Concrete Curing

Home–Concrete Finishing

CONCRETE Curing

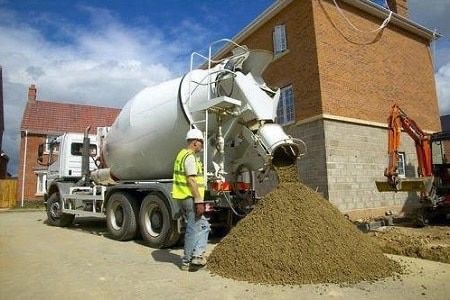

What Is Curing Of Concrete?

The process of protecting the moisture of concrete surface and enhancing the hydration of cement is known as curing. The physical properties of concrete totally depend on the

hydration of cement. If curing is not done properly concrete will be failed to acquire its full strength. Improper curing may also lead the concrete to crack.

Purpose Of Curing

- To Complete the hydration process between cement and water.

- To achieve the maximum strength of concrete.

- To prevent the concrete structure from cracking.

Methods Of Concrete Curing

01

Shading

By this method, the evaporation of water is locked in the concrete surface. It also protects the surface from heat, wind, etc. In cold climates, it prevents the concrete from freezing by preserving the heat of hydration of cement.

02

Covering The Surface

In this method, the concrete surface is covered with wet gunny bags or waterproof papers to avoid water loss and to protect the concrete from further damage. This method gives satisfactory results for concrete slabs and pavements.

03

Sprinkling Water

In this method, water is sprayed on the concrete with the help of nozzles at proper intervals. This method is not so effective due to the difficulty of keeping the concrete surface be moist all the time.

04

Ponding

Ponding is the most common method that is adopted for curing concrete floors, slabs, pavements, etc. In this method the concrete surface is first covered with a moist wrapper for 24 hours.

After that, the covers are then removed and a small amount of clay puddles are constructed around all the area. Then water is filled for final curing.

05

Membrane Curing

In this method concrete surface is covered by waterproof membranes or sealing compounds such as bitumen emulsion, wax, rubber latex emulsion, water repellant, plastic films, etc. The membrane protects the water loss from concrete. It is seen membrane curing for 28 days gives equivalent strength to two weeks of moist curing.

06

Steam Curing

Steam curing is done by increasing the temperature of concrete in wet conditions. This method allows the concrete to achieve its full strength within a short time, thus curing is also finished within a short time. Steam curing is mostly adopted for the production of precast members.

Shading

By this method, the evaporation of water is locked in the concrete surface. It also protects the surface from heat, wind, etc. In cold climates, it prevents the concrete from freezing by preserving the heat of hydration of cement.

Covering The Surface

In this method, the concrete surface is covered with wet gunny bags or waterproof papers to avoid water loss and to protect the concrete from further damage. This method gives satisfactory results for concrete slabs and pavements.

Sprinkling Water

In this method, water is sprayed on the concrete with the help of nozzles at proper intervals. This method is not so effective due to the difficulty of keeping the concrete surface be moist all the time.